High Speed Fully Automatic Square Bottom Food Sandwich Cookies Chocolate Fast Food Kraft Brown Paper Bag Making Machine Machinery Price Making Paper Bags

Overview Product Description This machine is designed to manufacture square bottom paper bags with handles from paper ro

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | ZD-QFJ |

| Speed | High |

| Width | 90-540 |

| Size and Shape | 14500×6000×3400 |

| Long | 220-770 |

| Weight | 23000 |

| Material | Paper |

| Usage | Shopping Bag, Leisure Food Bag, Bread Bags, Fruit Bag, Kfc Bag |

| Model No. | Zd-Qfj Series |

| Paper Roll Width | 310-1530mm |

| Paper Tube Length | 220-770mm |

| Paper Thickness | 50-170GSM |

| Bag Body Width | 90-540mm |

| Bag Bottom Size | 50-254mm |

| Max Speed | 220bags/Min |

| Transport Package | Vacuum Rustproof Composite Packaging, Wood Pallet |

| Specification | 14000*6000*3400mm |

| Trademark | Jianshe |

| Origin | Suzhou, China |

| HS Code | 84412000 |

| Production Capacity | 600sets/Year |

Product Description

This machine is designed to manufacture square bottom paper bags with handles from paper roll, paper patch roll and paper rope, and it is an ideal equipment for producing paper handbags fast. By implementing steps including handle making, handle application, tube forming, tube cutting and bottom forming within a fully automatic process, this machine can effectively save labor costs. The equipped photoelectric detector can correct cutting length, so as to ensure cutting precision. SIEMENS PLC system and adjustable dual-moulds structure, ensure that the machine can perform quickly and stably, as well as reduce adjusting time for different bag sizes. Special bags collection platform and counting function, improve packing efficiency of finished paper bags. Thanks to perfect technologies and fast production speed, this machine can produce paper handbags with high quality in many different forms, which are especially suitable for food and clothing industries.

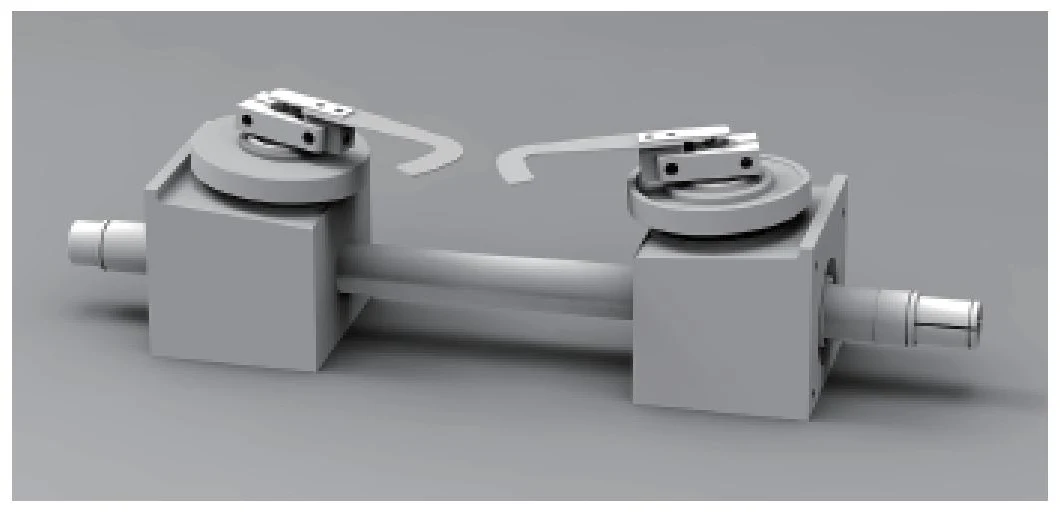

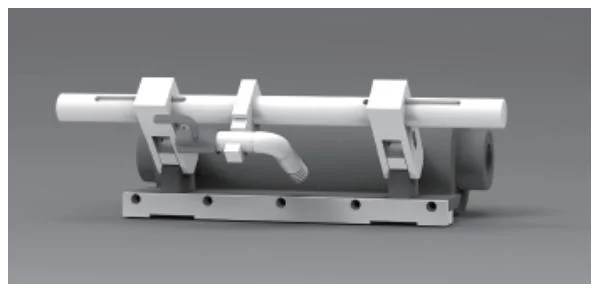

Detailed PhotosFeature1. Special bottom closing device improves the relatively slow bottom closing process in traditional models, so as to greatly enhance the bag making speed.2. Distinct bottom gluing system (water glue) can efficiently save glue loss and labor cost, bringing the profit to the customer directly during the production.3. Adjustable dual-moulds structure (own proprietary technology) is applied on the machine, so that users can adjust bag size directly on the machine, which greatly reduces bag size adjusting time and increase production capacity.4. SIEMENS PLC system ensures that the adjustment of cutting length can be implemented directly on touch screen, meanwhile brings efficient and stable production.5. Tube cutter can be equipped with serrated blade or straight blade freely, so as to meet customers' requirements to different bag mouths.6. This kind of machine can be connected with independent twisted handle machine and flat handle machine at the same time, so that users can not only save at least 40% investment and 45% space, but also be more flexible to paper bag market due to one-machine-two-usages.Product Parameters

| ZD-QFJ08 | ZD-QFJ11E | ZD-QFJ13E(S) | ZD-QFJ14 | ZD-QFJ18C | ZD-QFJ21(s) | |

| Paper Roll Width | 410-770mm(310-890mm) | 590-890mm(370-890mm) | 590-990mm(400-990mm) | 590-1150mm | 690-1280mm(650-1280mm) | 630-1530mm |

| Max. Paper Roll Diameter | Φ1200 mm | Φ1200 mm | Φ1200 mm | Φ1200 mm | Φ1200 mm | Φ1200 mm |

| Material Core Diameter | 76mm( 3'') | 76mm( 3'') | 76mm( 3'') | 76mm( 3'') | 76mm( 3'') | 76mm( 3'') |

| Paper Thickness | 50~140g/m² | 50~150g/m² | 80-160g/m² | 80-150g/m² | 80-160g/m² | 90-170g/m² |

| Bag Body Width | 140-220mm(90-220mm) | 200-280mm(110-280mm) | 200-330mm(125-330mm) | 200-360mm | 240-450mm(220-450mm) | 380-650mm(380-770mm) |

| Paper Tube Length | 230-370mm(220-470mm) | 270-410mm(270-530mm) | 270-410mm(270-530mm) | 350-650mm | 380-640mm(380-760mm) | 380-650mm(380-770mm) |

| Bag Bottom Size | 50-140mm | 60-150mm | 60-150mm(70-180mm) | 80-200mm | 90-180mm | 80-210mm(130-254mm) |

| Handle Rope Height | 80mm-85mm | 110-115mm | 110-115mm | 110-115mm | 110-115mm | 110-115mm |

| Handle Rope Diameter | Φ4-6mm | Φ4-6mm | Φ4-6mm | Φ4-6mm | Φ4-6mm | Φ4-6mm |

| Handle Patch Length | 114.3mm | 152.4mm | 152.4mm | 152.4mm | 190.5mm | 190.5mm |

| Handle Patch Width | 45-50mm | 45-50mm | 45-50mm | 45-50mm | 45-50mm | 45-50mm |

| Paper Patch Roll Diameter | Φ1200 mm | Φ1200 mm | Φ1200 mm | Φ1200 mm | Φ1200 mm | Φ1200 mm |

| Paper Patch Roll Width | 90-100mm | 90-100mm | 90-100mm | 90-100mm | 90-100mm | 90-100mm |

| Paper Patch Thickness | 100~180g/m² | 100-180g/m² | 100-180g/m² | 100-180g/m² | 100-180g/m² | 100-180g/m² |

| Max.Speed | 150bags/min(220bags/min) | 150bags/min(220bags/min) | 150bags/min(220bags/min) | 150bags/min(150bags/min) | 150bags/min(130bags/min) | 110bags/min(120bags/min) |

| Total Power | 28kw | 38kw | 38kw | 39kw | 43kw | 39kw |

| Total Weight | 15000kg | 18000kg | 18000kg | 20000kg | 20000kg | 23000kg |

| Over Dimension | L11000mm×W4400mm×H1800mm | L14000mm×W6000mm×H3400mm | L14000mm×W6000mm×H3400mm | L14000mm×W6000mm×H3400mm | L14000mm×W6000mm×H3400mm | L14000mm×W6000mm×H3400mm |

A: We are the manufacturer and have more than 200 workers

Q: Where is your factory located? May I have a visit?

A: Warmly welcome! Our factories are located in Suzhou and Wenzhou

Q: How is the quality of your machine?

A:History: Our company has nearly 30 years of manufacturing history.Size: Covering an area of 26,600 square meters; more than 100 processing & testing equipments.Products: Paper Bag Machines and Flexographic Printing Machines.Sales: Self-owned import&export rights; Annual output value is more than US$20,000,000

Q: What information should I let you know if I want to get a quotation?

A: First:Paper raw material: Roll-Fed paper or Sheet-Fed Paper.Second:sizes of the paper bag, thickness of paper.Then the most suitable machine will be reccomended to you.

Q: Do you have related machine working video?

A: Yes.

Related Products

-

![New World Hot Sale High Speed Food Paper Bag Making Machine]()

New World Hot Sale High Speed Food Paper Bag Making Machine

-

![All Types of Paper Cups and Paper Bowls Forming Machine]()

All Types of Paper Cups and Paper Bowls Forming Machine

-

![Automatic FIBC Jumbo Container Woven Bag Cutting Machine for Big Sack Making Machines]()

Automatic FIBC Jumbo Container Woven Bag Cutting Machine for Big Sack Making Machines

-

![Automatic High Speed Paper Cup Machine for Paper Cup, Paper Bowl, Drinking Cup, Coffee Cup and Tea Cup Forming machine]()

Automatic High Speed Paper Cup Machine for Paper Cup, Paper Bowl, Drinking Cup, Coffee Cup and Tea Cup Forming machine