Automatic Square Bottom Paper Bag Making Machine Price Making Paper Bags

Overview Package size per unit product 20.00cm * 20.00cm * 10.00cm Gross weight per unit product 5.000kg Automatic Squar

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | XKFD |

| After-sales Service | 12 Months |

| Warranty | 12 Months |

| Machine Type | Bag Forming Machine |

| Bag Type | Shopping Bag |

| Characteristic | Automatic Glue |

| Computerized | Computerized |

| Speed | High |

| Width | 150-330 |

| Size and Shape | 9800*3050*1900 |

| Long | 225-470 |

| Weight | 8000kg |

| Material | Paper |

| Usage | Shopping Bag, Leisure Food Bag, Bread Bags, Fruit Bag |

| After-Sales Service Provided | Field Installation, Commissioning and Training |

| Automatic | Computerlized |

| Servo Motor | Mitsubishi |

| Keywords | Paper Bag Making Machine |

| PLC | Mitsubishi |

| Function | Paper Bag Producing |

| Bag Width | 150-330mm |

| Bag Length | 225-470mm |

| Application | Food Packaging, Shopping Bag |

| Brand | Xinke |

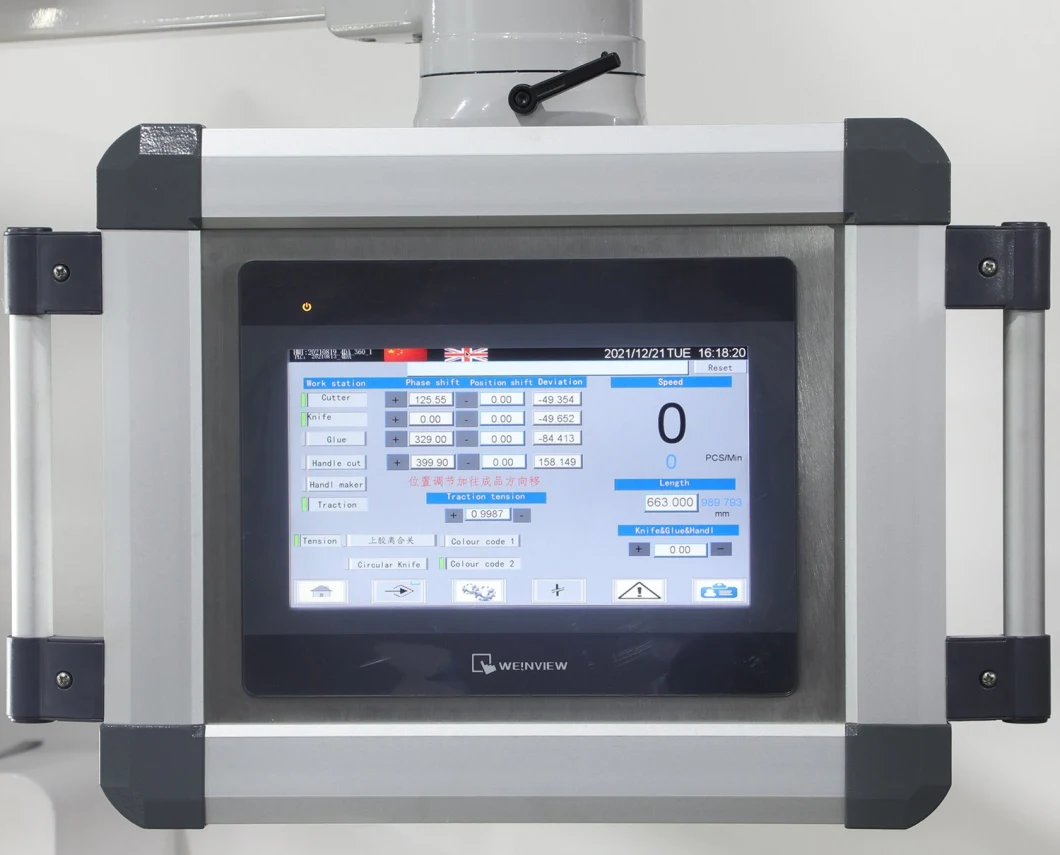

| Touch Screen | Weinview |

| Printing Tracking Electric Eye | Sick |

| Pneumatic Components | Airtac |

| Paper Thickness | 60-160GSM |

| Roll Paper Diameter | 1200mm |

| Transport Package | Packed in Wood Cartoon and Plastic Film |

| Specification | speed: 30-160pcs/min |

| Trademark | Xinke |

| Origin | China |

| HS Code | 8441200000 |

| Production Capacity | 200sets/Year |

Packaging & Delivery

Package size per unit product 20.00cm * 20.00cm * 10.00cm Gross weight per unit product 5.000kgProduct Description

Automatic Square Bottom Paper Bag Making Machine Price Making Paper Bags

This machine is composed of rolling paper feed (hydraulic feeding, automatic deviation correction, constant tension), side glue, printing paper electric eye tracking, original paper into roll, fixed length traction cutting, bag bottom indentation opening bottom, bag bottom gluing folding forming and bag output. The whole machine is controlled by the computer central control system, the touch screen display, and the servo motor controls the length of the paper bag.

According to customer needs, two/ four-color printing machine, Paper bag windowing device and paper bag hand holing device or paper handle bar device can be customized.Product Parameters

| Model | XKFD-220 | XKFD-280 | XKFD-330 | XKFD-450 | XKFD-540 |

| Paper Roll Length | 190-370mm (C) | 270-530mm(C) | 270-530mm (C) | 285-530mm (C) | 420-760mm (C) |

| Paper bag length | 150-320mm (L) | 225-470mm (L) | 225-470mm (L) | 225-470mm (L) | 320-680mm (L) |

| Paper bag width | 80-220mm (W) | 120-280mm(W) | 150-330mm (W) | 220-460mm (W) | 250-540mm (W) |

| Paper bag bottom width | 55-100mm (H) | 60-180mm (H) | 60-180mm (H) | 80-220mm (H) | 120-260mm (H) |

| Paper thickness | 50-130g/m2 | 60-160g/m2 | 60-160g/m2 | 80-160g/m2 | 90-160g/m2 |

| Bag Making Speed | 30-200pcs/min | 30-180pcs/min | 30-160pcs/min | 30-150pcs/min | 30-120pcs/min |

| Paper roll width | 290-670mm | 385-950mm | 445-1050mm | 630-1390mm | 770-1640mm |

| Roll paper diameter | 1300mm | 1300mm | 1300mm | 1300mm | 1300mm |

| Diameter of paper core | 76mm (3") | 76mm (3") | 76mm (3") | 76mm (3") | 76mm (3") |

| Machine power | 3phase,380v, 10kw | 3phase,380v,12kw | 3phase,380v, 12kw | 3phase,380v,15kw | 3phase,380v,18kw |

| Machine weight | 5500kg | 7000kg | 8000kg | 10000kg | 13000kg |

| Machine size | 8000x2980x1800mm | 9700x2980x1900mm | 9800x3050x1900mm | 10200x3150x2200mm | 11250x3400x2160mm |

·Touch Screen

PC control system with touch screen interface is adopted to display the working status in real time. With super precision servo motor drive to ensure the stability of production products.

·Integral tube Adjustment structure

The integral cylinder adjustment structure improve work efficiency, reduces the scrap rate generated during the adjustment process, and saves adjustment time and adjustment stability.

·Mechanical Transmisson Compact Desigh

The compact design of mechanical transfer ensures stable and accurate material transfer, improves mechanical performance, and produce paper bags that are more beautiful and tidy.

·Color Mark Tracking System

Automatic matching function of color, which eliminates the need to change the paper reel, cut off the paper, need to re-adjust the cutting position after power failure. Code code error automatic stop, save precious time, reduce the rejection rate.

·Hydraulic Auto Rewinding Part

Feeding part the max diameter of roll is 1300m. Machine adopt large air cylinders automatically up, it running by hydraulic station.

Production Process

1.Quality Commitment: one year guarranty,Lifelong maintenance, Vulnerable parts are provided free of charge within 12 months.

2. After-sales Service: 24hours online to help customer solve problem.3. Operation Guide: after the customer receives the goods, the engineer will guide the installation throughout.4. Machine Parts: all machine parts are imported from famous imported brands, which are convenient for customers to repair and buy by themselves.FAQ1. Who are we?We are based in Zhejiang, China, start from 2000,sell to Domestic Market(15.00%),South Asia(15.00%),SoutheastAsia(15.00%),SouthAmerica(11.00%),North America(9.00%),Africa(8.00%),Oceania(8.00%),Mid East(7.00%),Eastern Europe(7.00%),Central America(5.00%).There are total about 50 people in our office.2. How can we guarantee quality?Always a pre-production sample before mass production;Always final Inspection before shipment;3. What can you buy from us?Paper Bag Making Machine, Printing Machine, Slitting Machine and Handle Machine.4. Why should you buy from us not from other suppliers?We have more than 20 years of rich experience for machinery manufacturing.5. What services can we provide?Accepted Delivery Terms: FOB,CFR,CIF,EXW;Accepted Payment Currency:USD,EUR,CNY;Accepted Payment Type: T/T,L/C,Western Union,Cash;Language Spoken:English,Chinese,Russian and Spanish.

Related Products

-

![Plastic&Paper Double Stand up Zipper Doypack Pouch Making Machine]()

Plastic&Paper Double Stand up Zipper Doypack Pouch Making Machine

-

![Automatic Hamburger/Burger/Lunch Paper Box/Kfc/Macdonald′ S Fast Food/Pizza Bag Box/ Paper Tray Express Bag Cup Plate Forming Making Machine]()

Automatic Hamburger/Burger/Lunch Paper Box/Kfc/Macdonald′ S Fast Food/Pizza Bag Box/ Paper Tray Express Bag Cup Plate Forming Making Machine

-

![Price 4 Lines HDPE, LDPE Plastic Nylon Flat Garbage Bag Heat Bottom Sealing Cold Cutting Non Woven Automatic Shopping Bag Making Machine for Biodegradable PLA]()

Price 4 Lines HDPE, LDPE Plastic Nylon Flat Garbage Bag Heat Bottom Sealing Cold Cutting Non Woven Automatic Shopping Bag Making Machine for Biodegradable PLA

-

![Price Fully Automatic with Ultrasonic Online Handle Sealing Non Woven Fabric Box Bag Shopping Bag T Shirt Bag D Cut Vest Bag Stringing Shoe Bag Making Machine]()

Price Fully Automatic with Ultrasonic Online Handle Sealing Non Woven Fabric Box Bag Shopping Bag T Shirt Bag D Cut Vest Bag Stringing Shoe Bag Making Machine